Hotwaterwizard

Hotsy Service Tech

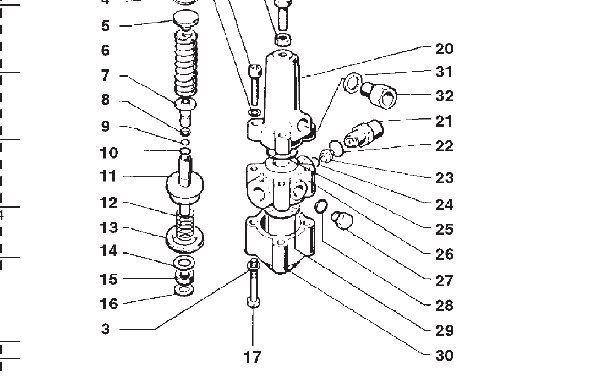

There is a battle going on between the experts on which unloader is better. Flow sensitive or Pressure sensitive.

Which one is better to the guys that use the machines?

1) Flow sensitive.

When you pull the trigger on the gun, the pressure increases slowly as the flow increases. There is a short delay each time you pull the trigger. This unloader relieves all of the pressure from the gun and hose each time the trigger is released.

2) Pressure sensitive.

Sometimes called lock-up unloader. When you pull the trigger you get a sudden burst of pressure at the beginning then it levels off to a steady pressure. When you let go of the trigger the pressure will climb up to the set pressure and stay there in your hose untill you pull the trigger again.

Here is the debate if any one would like to join the experts.

Is it better for heating coils made of metal to expand to the set pressure of an unloader then back down to zero or, is it better to go from the set level up to the set level.

in easy terms here is another way to say it.

If your machine puts out say 3000 psi.

Is it better on the metal to go from 0 to 3000 psi then 3000 psi back to 0 (Flow Unloader) or, is it better to go from 3000 psi up to 3500 psi and back down to 3000 psi again. (Pressure Unloader)

__________________

Hotwaterwizard@aol.com If You have a problem with your machine, just ask I'll help if I can.

Which one is better to the guys that use the machines?

1) Flow sensitive.

When you pull the trigger on the gun, the pressure increases slowly as the flow increases. There is a short delay each time you pull the trigger. This unloader relieves all of the pressure from the gun and hose each time the trigger is released.

2) Pressure sensitive.

Sometimes called lock-up unloader. When you pull the trigger you get a sudden burst of pressure at the beginning then it levels off to a steady pressure. When you let go of the trigger the pressure will climb up to the set pressure and stay there in your hose untill you pull the trigger again.

Here is the debate if any one would like to join the experts.

Is it better for heating coils made of metal to expand to the set pressure of an unloader then back down to zero or, is it better to go from the set level up to the set level.

in easy terms here is another way to say it.

If your machine puts out say 3000 psi.

Is it better on the metal to go from 0 to 3000 psi then 3000 psi back to 0 (Flow Unloader) or, is it better to go from 3000 psi up to 3500 psi and back down to 3000 psi again. (Pressure Unloader)

__________________

Hotwaterwizard@aol.com If You have a problem with your machine, just ask I'll help if I can.